Pulsating vacuum sterilizer is strictly designed and manufactured in accord with GMP technical Standard. It has passed ISO9001 quality management qualification standard and ISO13485:2003 Certificate of Quality Management System for Medical Devices. The relevant data and curve can be saved and printed automatically. This autoclave is suitable for pharmaceutical factory, hospital, scientific research institute and other units to sterilize and dry asepsis clothes, rubber goods, metal instruments, culture medium, etc.

Medical Waste Sterilization Equipment Vacuum Steam Sterilizer Description:

Application scope:

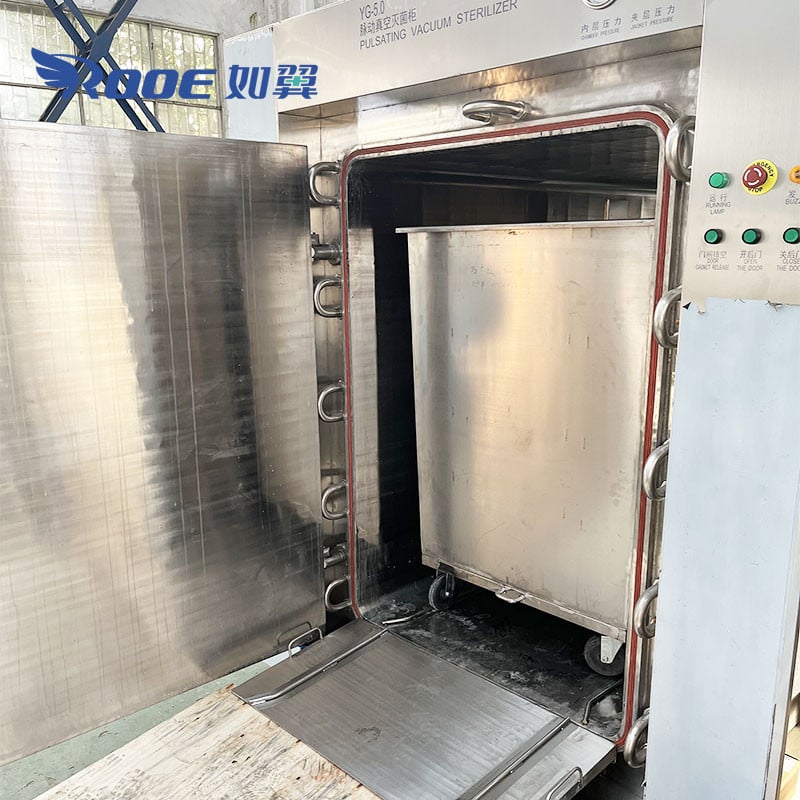

Medical waste equipment is used for sterilization of medical waste. Medical waste is infectious waste mainly produced by hospitals, health and epidemic prevention units, sanatoriums for patients, medical research units, etc., mainly including:

| Waste Dressing | Medical Glove | Syringe |

| Infusion Set | Blood transfusion apparatu | Test Tube |

| Filter | Apron | Glove |

| Waste Needle | Scalpel | Surgical Saw |

| Broken Glass | Expired Drug | Ampoule |

| Other medical waste | ||

Quality system:

Designed and manufactured in accordance with ISO 9001-2000 and ISO 13485-2003 quality management systems.

Environmental protection system:

Using tap or chilled water supplies can reduce water consumption by up to 90%, making your facility greener and more cost effective.

The distilled water and discharged gas are treated with environmental protection, no pollution and zero infection.

Safety system:

Hospital robustness with multiple security structures including overpressure protection, low water level protection, door interlocking system, overload and short circuit protection to ensure operational security.

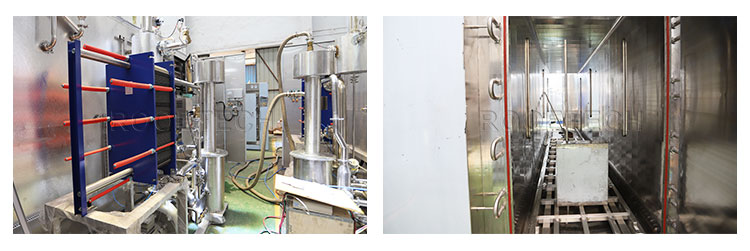

Vacuum system:

Vacuum system is used to deal with cold air and keep the temperature of the chamber uniform. All air leaving the chamber prior to sterilization is considered highly infectious and made sterile by a rigorous biological purification system.

Sterilization procedure:

- Automatic and manual operation mode;

- Automatic operation mode:

Microbial inactivation:

After sterilization, the number of microorganisms is reduced to less than 10-6.

YG Hospital Medical Waste Sterilization Equipment Vacuum Steam Sterilizer Features:

1. With double jacket construction, complete recessed jacket should be provided around the chamber to avoid steam condensation and promotion, and appropriate temperature distribution. It can be heated evenly to prevent the material from uneven heating.

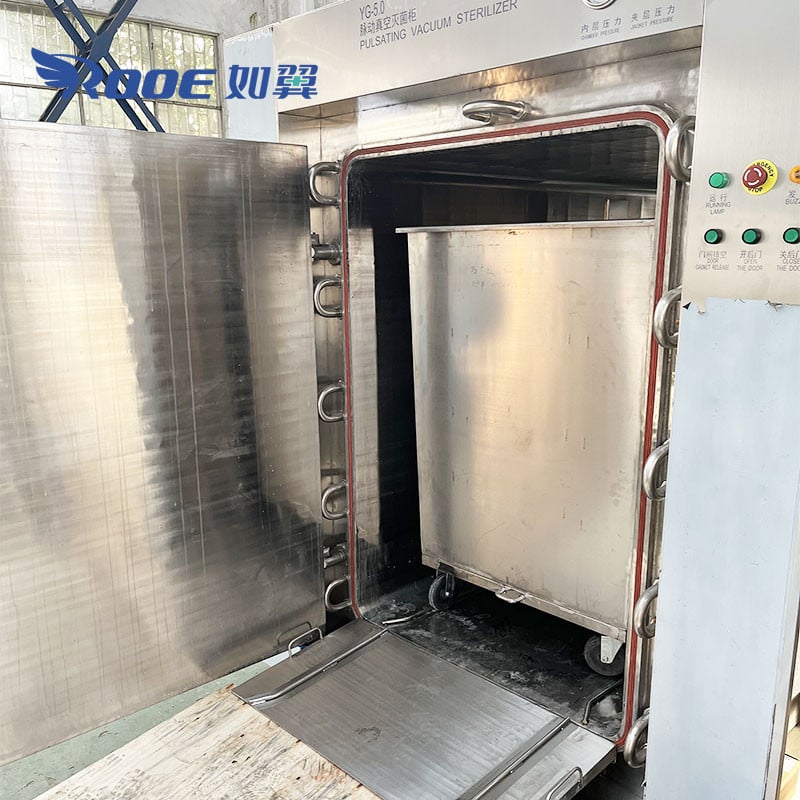

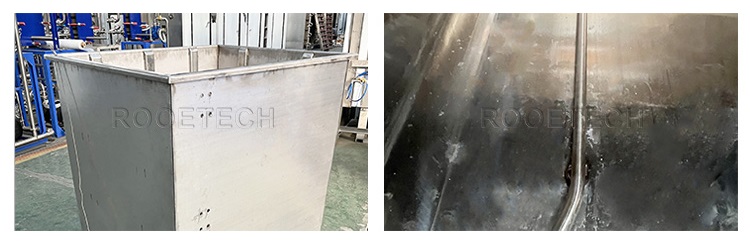

2. Chamber: the chamber is made of SUS316L, according to mechanical and chemical treatment, the surface of the chamber is bright, the Angle of the chamber is arc transition, no cleaning dead Angle, corrosion resistance. Two stainless steel guide rails shall be provided in the chamber as the rails for the loading car.

3. The insulation layer is made of aluminosilicate, the best insulation material, and the equipment is rectangular with stainless steel decorative cover.

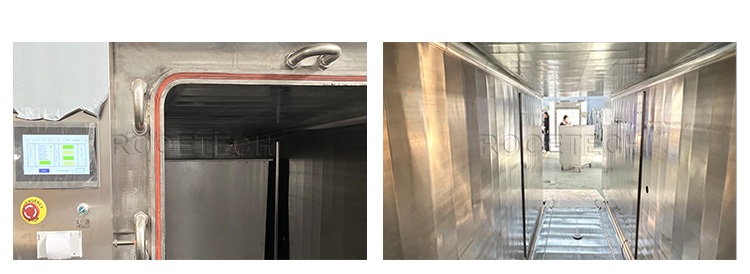

4. The door:

- Autoclave design is straight-through (double door) autoclave. Front and rear doors won't open at the same time.

- The door seal is inflatable, pressurized with compressed air and can withstand chamber temperature and pressure.

- The door shall have a safety mechanism to prevent the door from opening when the chamber is hot or pressurized or when pressurized in an autoclave.

- Sterilization cycle can only be started after the door is completely closed and locked.

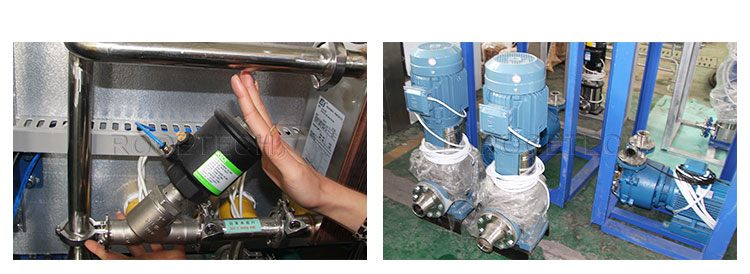

5. Pipeline system consists of filter, vacuum pump, pneumatic valve and so on.

- Air filters are Pall brand. Excellent performance, no medium fracture or pollution unloading.

- Vacuum pump: Autoclave includes liquid ring vacuum pump to obtain vacuum in the chamber, ensuring proper air removal for excellent sterilization.

- Angle pneumatic valve: strong on/off valve, without any error, remote compressed gas control. Stainless steel clamp seat for inner cabin.

6. Control system:

-PLC + HMI control +Micro- data printing, should be able to default one or more sterilization cycles. Electrical equipment system adopts domestic or imported parts, its performance is stable and reliable.

- Advanced control function, large storage capacity, trouble-free operation time up to 50,000 hours.

- Primary controller system: You can set the user name and password, and set different users to access the system. It has three interface functions: manager, user and maintainer. The administrator can set the password according to different levels of use, to ensure the use of security, to prevent improper operations or modify the program to bring about experiments.

- When the automatic controller is in failure, the safety device keeps the sterilization chamber pressure safe under the atmosphere pressure to the back of the state and allows the loading door to be opened.

- Manual operations can be done using access control tools for maintenance, testing and emergency needs.

7. Touch screen:

- Display working process parameters, simple control, easy to operate.

8. The interface has the following functions:

- Display screen shows sterilization cycle status, time, pressure, temperature, double door density, operation record, printing and other processes.

Printer: real-time output can be realized by micro needle printer, which can easily output "pressure, temperature, time, F0 value" and other parameters and curves.

- The autoclave has an emergency stop mechanism designed to immediately stop all physical movement of the device.

- Fixed GMP validation connector can provide GMP validation for customers free of charge.

| Design pressure | 0.245Mpa | Vacunm | -0.095Mpa |

| Working Pressure | 0.22Mpa | Steam Source Pressure | 0.4-0.6Mpa |

| Design Temperature | 139℃ | Water Source Pressure | 0.1-0.3Mpa |

| Working Temperature | 134℃ | Compressed Air Pressure | 0.5-0.7Mpa |

| Specifications | Overall Dimensions | Chamber Size | Steam Consumption | Power | Water Consmption | Net Weight |

| Model | L*M*H(mm) | L*W*H(mm) | (kg/cycle) | (KW) | (kg/cycle) | (kg) |

| Single/Double Door | ||||||

| YG-0.1 | 825*1080*1600 | 630*400*480 | 15 | 1 | 80 | 380 |

| YG-0.25 | 895*1220*1720 | 760*600*600 | 20 | 1.5 | 150 | 650 |

| YG-0.36 | 1195*1220*1720 | 1000*600*600 | 25 | 1.5 | 150 | 760 |

| YG-0.6 | 1245*1300*1880 | 1050*680*850 | 30 | 2 | 200 | 1100 |

| YG-0.8 | 1595*1300*1880 | 1400*680*850 | 35 | 3 | 250 | 1300 |

| YG-1.2 | 1695*1370*1960 | 1500*750*1100 | 40 | 3 | 300 | 1900 |

| YG-2.5 | 3195*1370*1960 | 3000*750*1100 | 75 | 4.5 | 450 | 2800 |

| YG-5.0 | 3635*1800*2200 | 3400*1000*1500 | 150 | 7.5 | 600 | 4500 |

YG 5.0 Steam Autoclave:

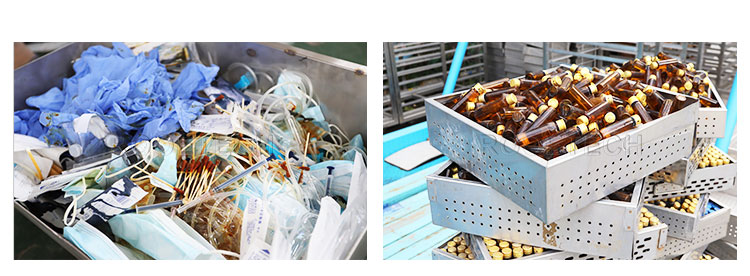

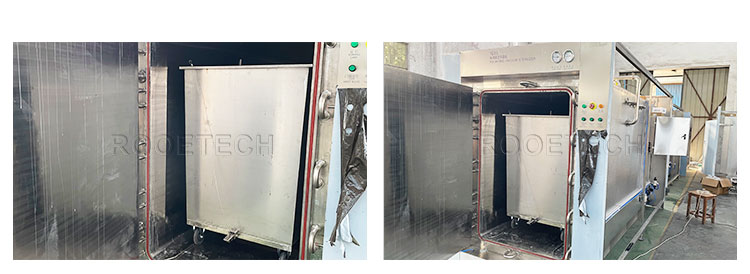

YG 0.6 Series Autoclave:

Medical Waste Disposal:

Circular Chamber Construction:

Rectangular Chamber Construction: