The Vacuum Negative Pressure Unit is a compact and efficient solution designed specifically for medical applications. Utilizing advanced oil-free negative pressure technology, it delivers clean, stable vacuum performance without the risk of oil contamination. Ideal for use in operating rooms, intensive care units, and dental clinics, this system ensures a hygienic environment, easy installation, and intelligent control for reliable 24/7 operation.

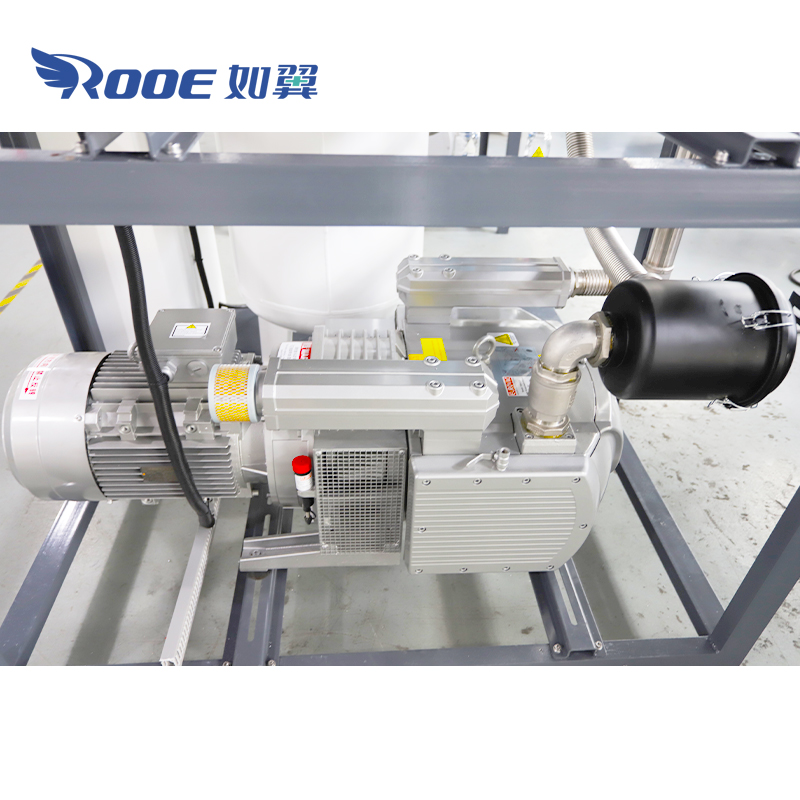

This Oil-free Negative Pressure Unit is a highly integrated solution tailored for demanding medical environments. Featuring a 5.5KW dual-head vacuum pump delivering 7.5HP of output power, it operates under a three-phase 220V (L-L), 60Hz special voltage configuration. With its reliable performance, energy efficiency, and user-friendly maintenance, this unit is ideal for operating rooms, ICUs, dental clinics, and any department requiring a consistent and contamination-free vacuum source.

|  |

|  |

1.Compact Modular Design for Easy Setup

The system adopts a compact, skid-mounted modular structure that unifies the vacuum pump, control cabinet, buffer tank, and related components. This design simplifies transportation and on-site installation while reducing piping complexity and installation time.

2.Oil-free Operation for Medical-Grade Cleanliness

By utilizing advanced oil-free compression technology, this unit eliminates the risk of oil vapor contamination, ensuring compliance with strict hospital hygiene standards. It also lowers long-term maintenance and operating costs.

3.Medical-grade Filtration and Sterilization

The unit is fitted with high-efficiency bacterial filters and an exhaust sterilization system that meets BS3928 standards. This ensures a clean vacuum pipeline and minimizes the risk of airborne microbial contamination within clinical environments.

4.Advanced PLC Intelligent Control

An integrated PLC system with an intuitive touchscreen interface provides real-time monitoring of operational parameters, alarms, and system settings. Safety features such as automatic restart after power loss and motor reverse protection enhance operational stability.

5.Remote Monitoring and Communication

Equipped with a standard communication interface, the unit can be seamlessly connected to hospital central monitoring systems. This enables remote operation, diagnostics, and real-time data acquisition, elevating the overall automation level of the facility.

| Model | Single-Unit Flow Rate (m³/h) | Single-Unit Power (kW) | System Flow Rate (m³/h) | Weight(kg) | Machine Size(L*M*H/mm) | Number of negative pressure machines |

| GAS-AIR-1.5Ⅱ | 62 | 1.5 | 124 | 270 | 1820*850*1300 | 2 |

| GAS-AIR-2.2Ⅱ | 100 | 2.2 | 200 | 310 | 1820*850*1300 | |

| GAS-AIR-2.7Ⅱ | 120 | 2.7 | 240 | 340 | 1820*850*1300 | |

| GAS-AIR-3.0Ⅱ | 150 | 3 | 300 | 360 | 1820*850*1300 | |

| GAS-AIR-4.0Ⅱ | 215 | 4 | 430 | 450 | 1600*1200*1850 | |

| GAS-AIR-5.5Ⅱ | 300 | 5.5 | 600 | 490 | 1600*1350*1850 | |

| GAS-AIR-9.0Ⅱ | 400 | 9 | 800 | 870 | 2700*1450*1850 | |

| GAS-AIR-11.0Ⅱ | 500 | 11 | 1000 | 1050 | 2700*1450*1850 | |

| GAS-AIR-1.5Ⅲ | 62 | 1.5 | 186 | 180 | 2400*1200*1850 | 3 |

| GAS-AIR-2.2Ⅲ | 100 | 2.2 | 300 | 300 | 2400*1200*1850 | |

| GAS-AIR-2.7Ⅲ | 120 | 2.7 | 360 | 360 | 2400*1200*1850 | |

| GAS-AIR-3.0Ⅲ | 150 | 3 | 450 | 450 | 2400*1200*1850 | |

| GAS-AIR-4.0Ⅲ | 215 | 4 | 645 | 633 | 2400*1350*1850 | |

| GAS-AIR-5.5Ⅲ | 300 | 5.5 | 900 | 900 | 2400*1350*1850 | |

| GAS-AIR-9.0Ⅲ | 400 | 9 | 1200 | 1200 | 3300*1400*1850 | |

| GAS-AIR-11.0Ⅲ | 500 | 11 | 1500 | 1500 | 3300*1400*1850 |